MENU

OUR WORK

PERFORMANCE

AT THE HIGHEST

LEVEL

Proof of performance.

MORE WORK

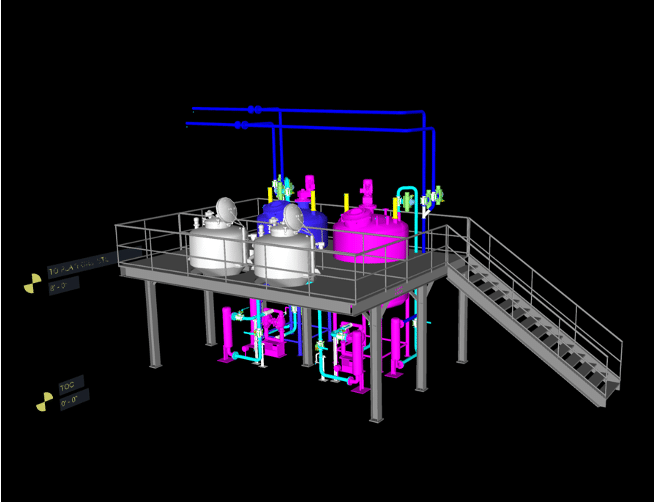

SPECIALTY CHEMICALS

- LOCATION:

- SIZE:

SERVICES

- Project Management

- Process, mechanical, electrical and controls design

- Plant and site planning

- Multidiscipline detailed engineering

- 3D modelling and construction work packages

PROJECT DESCRIPTION

- New facility on existing site bringing new products to the North American market

SPECIALTY CHEMICALS

FILLING LINE HOLDING TANKS

- Engineered, procured, installed and commissioned a holding and mixing production cell to feed a new filling line.

- Using our Virtual Plant Design workflow all major systems were pre-manufactured off site to reduce downtime to less than 2 weeks.

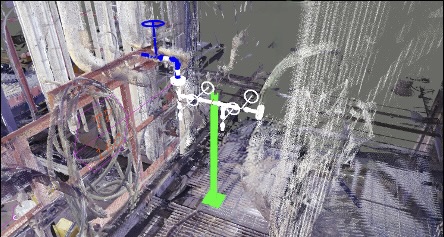

SPECIALTY CHEMICALS

- location:

- SIZE:

SERVICES

- Process, mechanical, electrical and controls design

- Plant and site planning

- Multidiscipline detailed engineering

- 3D VDC modelling

- Owner’s representative for construction

PROJECT DESCRIPTION

- Remove equipment from Ontario plant and ship to Rhode Island

- Using 3D laser scanning, fit the equipment into an existing low headroom building (21’ clear)

- Project was executed on a compressed scheduleduring the Covid19 pandemic

OIL & GAS

piping modification packages

- 3D laser scanning of 27 piping packages

- 3D modelling of the piping

- Dimensional ISOs for pre-fabrication

- Using our Virtual Plant Design workflow, we were able to identify discrepancies in traditional engineering packages ahead of the turnaround and eliminate costly rework.

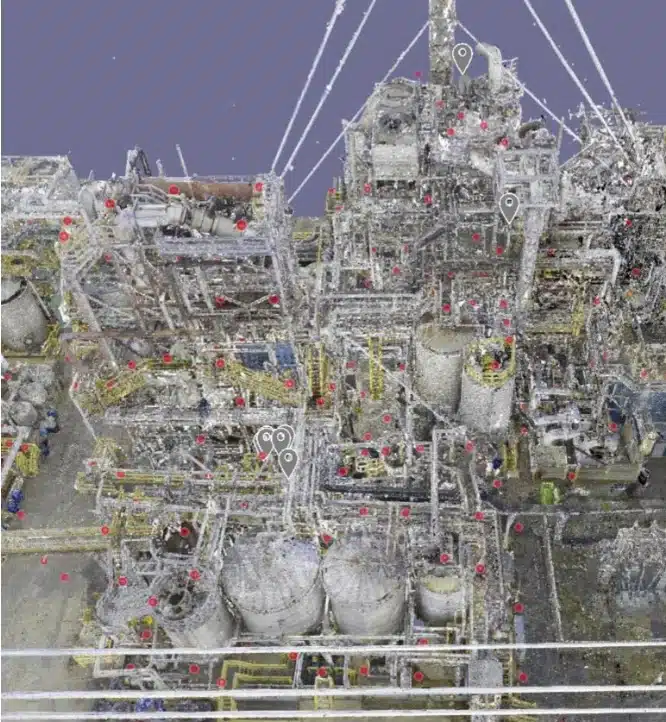

OIL & GAS

reformer turnaround precision planning

- Deploy state-of-the-art scanning technology

- Assess and predict hot & cold thermal expansion for complex tubing and piping

- Model changes to ensure minimum downtime in a high intensity environment

- Creating confidence based on precision & accuracy

CHEMICALS

scan to p&id

- Legacy plant was without current P&IDs

- From laser scan data and close collaboration with the site 60+ P&IDs were generated

OIL & GAS

RIK NAPHTHA PIPE

- 3500’ of 10” pipe

- 100% shop fabricated along with each individual pipe support

- No field welding

- The result was $1MM in savings on the projectand 3 months on the schedule.