MENU

PERFORMANCE

AT THE HIGHEST

LEVEL

If you’ve explored our site, you understand that we possess extensive experience. In this Gallery, we provide tangible proof of our performance. There’s a saying in Texas that describes someone who can’t back up their words with action: “all hat, no cattle.” We invite you to judge for yourself whether we have the cattle.

MAJOR PROJECTS

PHASE 1 PLANT RELOCATION

The project in Columbus, Georgia represents a significant investment for our client, with Phase 1 valued at $65 million USD. It requires a comprehensive approach to engineering and design, emphasizing innovation and precision to meet the demands of a modern industrial facility. The scope of work includes a wide range of specialized services, such as process, mechanical, and electrical design, as well as plant and site planning. Additionally, the project incorporates multidisciplinary detailed engineering, ensuring that all aspects of the facility are thoroughly planned and executed. Advanced 3D modeling techniques are utilized to create detailed construction work packages, providing clarity and efficiency throughout the construction process.

By consolidating production at the new site, the project aims to optimize operational efficiency and improve overall performance. The engineering team’s expertise, combined with cutting-edge technology and detailed planning, ensures that the facility will meet the client’s requirements while adhering to industry standards.

BROWNFIELD PLANT

In Cleveland, Ohio, an ambitious project took shape with a budget of US$85 million. This new facility, built on an existing site, aimed to introduce innovative products to the North American market.

The project included a comprehensive range of services, such as project management, process design, and detailed plant and site planning. A team of skilled engineers engaged in multidiscipline detailed engineering, ensuring that every aspect of the facility met the highest standards.

Advanced 3D modeling techniques were employed to create detailed construction work packages, facilitating a seamless building process. This initiative not only enhanced production capabilities but also marked a significant step forward in bringing cutting-edge products to consumers across the continent.

PLANT RELOCATION

In Providence, Rhode Island, a challenging US$10 million project unfolded, focusing on the relocation of equipment from an Ontario plant to a low headroom building with just 21 feet of clear space. The initiative involved a range of services, including process design, plant and site planning, and multidiscipline detailed engineering.

To ensure a precise fit within the existing structure, the team employed advanced 3D VDC modeling and utilized 3D laser scanning techniques. This meticulous planning allowed for the effective integration of the equipment into the limited space.

As the project progressed, it encountered the unique challenges posed by the Covid-19 pandemic. Despite these obstacles, the team executed the project on a compressed schedule, demonstrating remarkable adaptability and commitment. The successful relocation optimized the facility’s capabilities and underscored the team’s dedication to overcoming adversity in the face of unprecedented circumstances.

SUSTAINING PROJECTS

New storage tank

The project involved the removal of two old tanks from the indoor tank farm and the installation of a new storage tank along with its associated pump, filter, piping, and instrumentation.

Utilizing a Virtual Design and Construction (VDC) approach, the team adopted a scan-model-manufacture-assemble methodology. This allowed all components to be manufactured, modularized, and staged effectively to maximize off-site manufacturing efficiencies.

By carefully planning and executing each phase, the project not only modernized the facility but also enhanced operational capabilities. The successful integration of the new tank system marked a significant step forward in the facility’s efficiency and reliability.

CUSTODY TRANSFER METERING SYSTEM

The project involved the installation of two custody transfer metering systems for flammable liquids, both approved for use in Canada. This upgrade was crucial in minimizing the railcar off-loading shutdown window, enhancing operational efficiency.

Employing a Virtual Design and Construction (VDC) approach, the team utilized a scan-model-manufacture-assemble methodology, ensuring that all piping was 100% pre-manufactured off-site. This meticulous planning and execution not only streamlined the installation process but also ensured that the systems were integrated seamlessly into the existing infrastructure. The successful completion of this project significantly improved the facility’s metering capabilities and reduced downtime during off-loading operations.

COMBUSTIBLE DUST COLLECTION IMPROVEMENTS

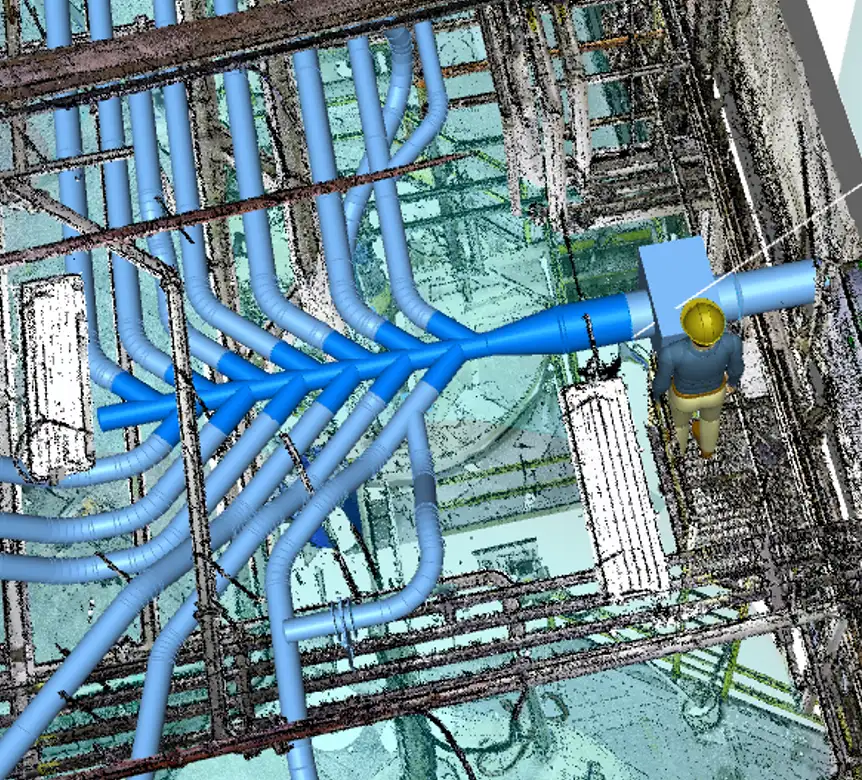

A dust hazard analysis (DHA) was performed according to NFPA 652 (Standard on the Fundamentals of Combustible Dust) on starch handling for one specific process. The lessons learned during that DHA led to a plant-wide review of the handling of dry solids at the site. This review identified the need for a dedicated dust collection system for multiple tanks at the plant that was suitable for the collection of combustible dust. The system included the reuse of an existing dust collector retrofitted with an upsized fan, explosion vent, explosion isolation flap valve and a distribution header with 13 duct branches.

It is worth noting that the 13 branches of ducting and distribution header were prefabricated off-site and assembled on-site with minimal rework. This is despite the tangle of existing pipes, conduit and equipment already occupying the space. A 3D laser scan of the area generated the point cloud that was used to design the system in AutoCAD. The benefits of this approach include decreased contractor time on site and risk of safety incidents.

FIRE WATER PIPING

The project focused on the installation of 1,600 feet of 6-inch fire water piping, which was entirely shop fabricated along with each individual pipe support. This approach eliminated the need for any field welding, streamlining the installation process significantly.

As a result of this efficient method, the project achieved a remarkable 30% savings. The careful planning and execution not only enhanced safety and reliability but also demonstrated the effectiveness of prefabrication in reducing costs and improving overall project timelines

STEAM TURBINE REPLACEMENT

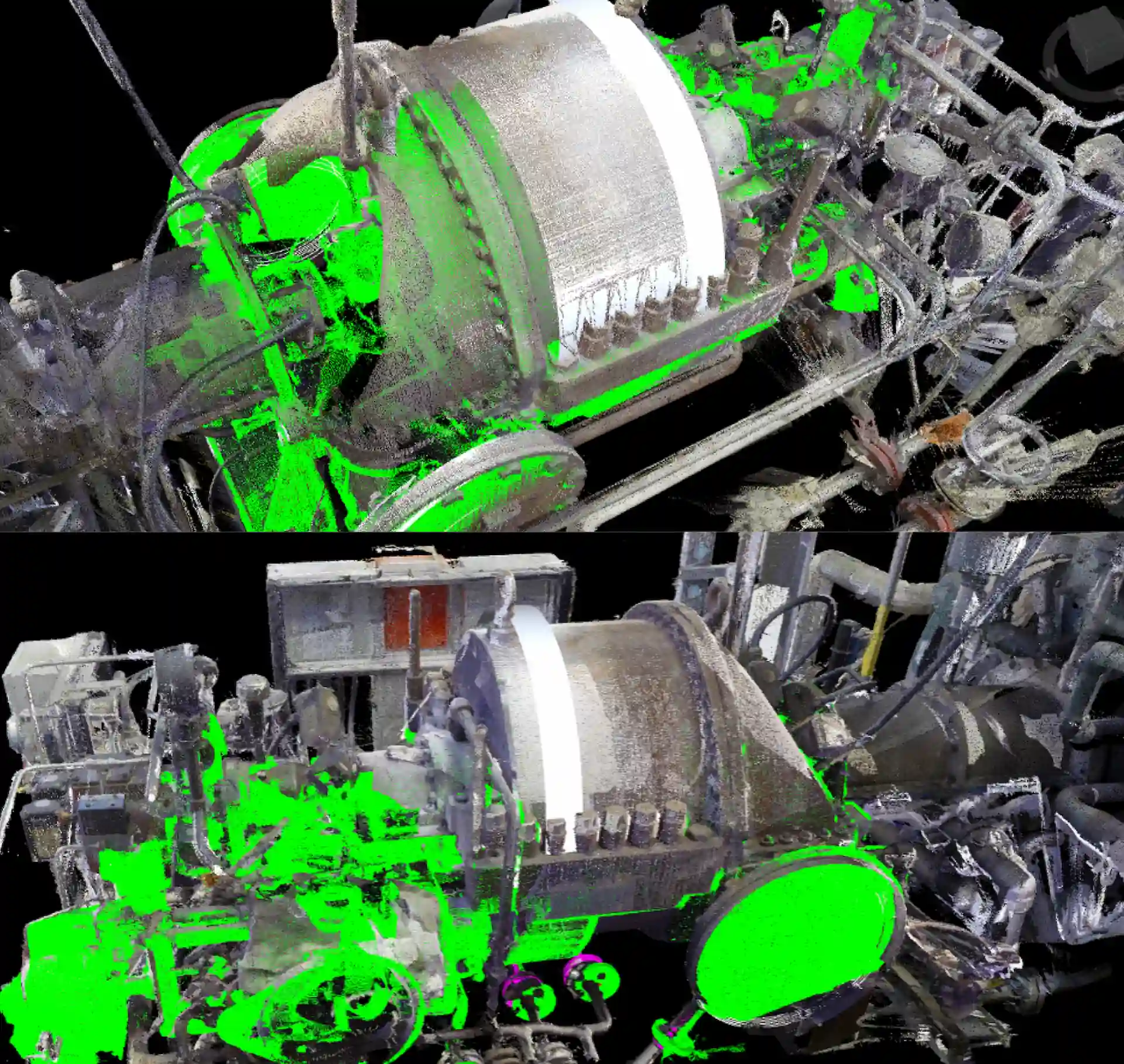

The steam turbine replacement project began with a comprehensive 3D laser scan of the existing steam turbine in its installed position. Additionally, a scan of the replacement steam turbine was conducted in the shop.

By comparing the two turbine point clouds, the team identified any deviations between the existing and replacement units. Utilizing this 3D scanning workflow allowed for the early detection of discrepancies, which proved invaluable ahead of the planned turnaround. This proactive approach not only facilitated a smoother installation process but also minimized potential delays, ensuring that the project progressed efficiently and effectively.